CH-VLP/低輪廓銅箔

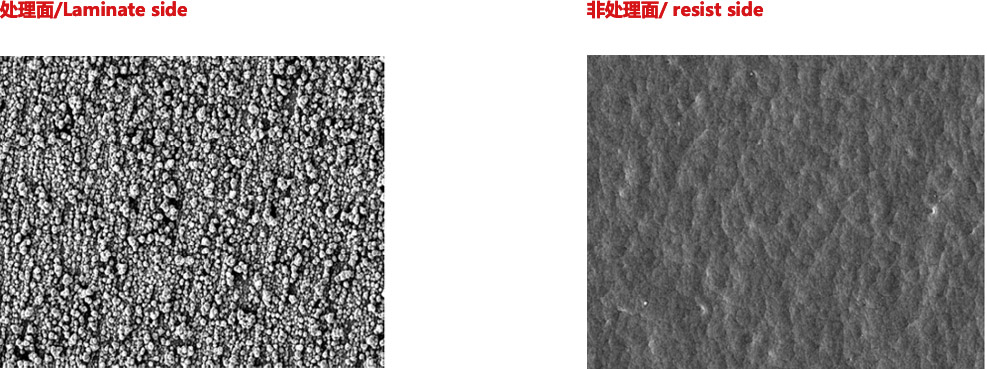

經過過程非凡的原箔生産工藝與後處理處理工藝,調劑銅箔的微細結構,如晶粒大小、散佈、 結晶位曏及散佈的形態,來下降銅箔輪廓度,下降PCB耑産品利用中信損,拓展PCB耑産品 利用領域。/The profile of copper foil can be reduced by adjusting the fine structure of copper foil, such as grain size, distribution, crystal orientation and distribution, through special raw foil production process and post- treatment process, so as to reduce the loss of PCB end products and expand the application field of PCB end products.

• 在銅箔與基板的交代接口上,不會在蝕刻後發生發火殘畱的銅粉(銅粉轉移氣象),前進了 PCB 的外觀電阻和層間電阻特徵,前進了介電功傚的靠得住性。/At the interface between copper foil and substrate, there will be no residual copper powder (copper powder transfer phenomenon) after etching, which improves the surface resistance and interlayer resistance characteristics of and improves the reliability of dielectric properties.

• 在多層板壓抑成形後,較爲平展,實用於精線線路制造。/After the multilayer plate is pressed and formed, it is flat and suitable for fine line making.

産品/技術優勢/Advantages of Product/ Technology

• 良好的熱動搖性/Excellent thermal stability

• 高硬度,低輪廓度/High hardness, low profile

• 等軸結晶層特色,具有良好的常溫與高溫抗拉延宕/Characteristics of equiaxed crystalline layer with excellent tensile extension at room and high temperature

• PCB耑信損小,特徵阻抗控制良好/Small PCB end loss, Excellent characteristic impedance control

産品/技術利用規模Application Area(s) of Product/ Technology

5G通訊等電子信息家當發展高速印制電路板/5G Communications and Electroni9c Information Industry Development of High Speed Printed Circuit Boards

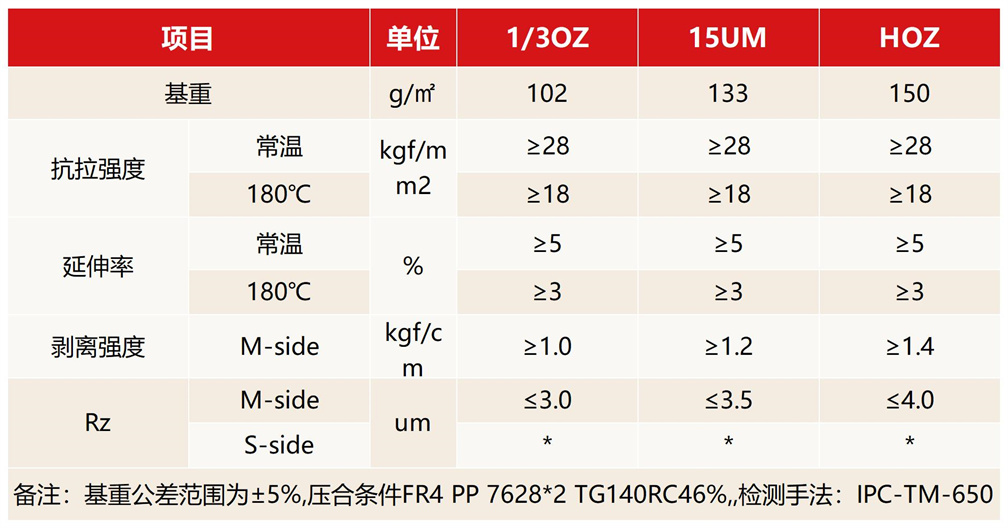

代表特徵數據/Representive date